Approach buffers

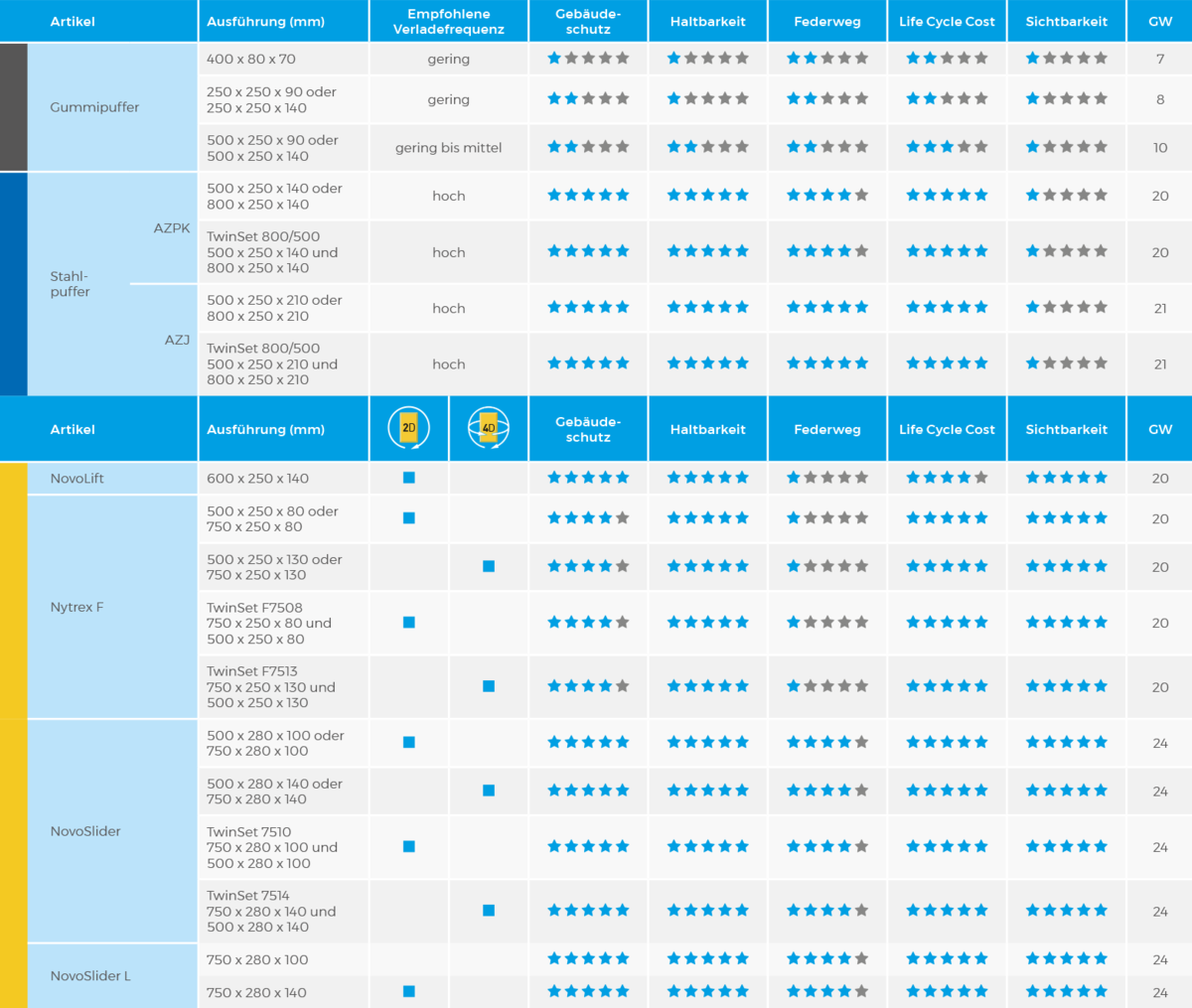

Nytrex dock bumper

Nytrex is a high-strength plastic that is also used in crane construction. The material has unique advantages for dock bumpers. In addition to the very good visibility for truck drivers, the high strength combines with a sliding ability to give the dock bumper a very long service life. The Nytrex dock bumper lasts 7-10 times longer than rubber! The available dimensions are compatible with corresponding mounting plates for rubber bumpers. For a better spring effect, a rubber plate is inserted between the steel plate and the Nytrex material

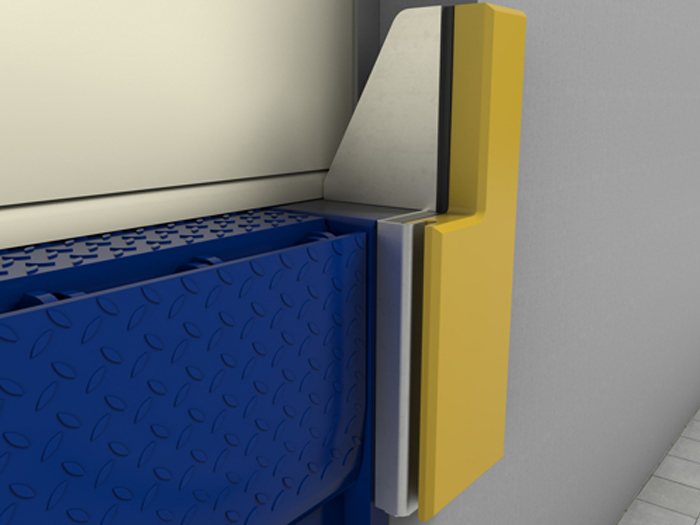

For telescopic lip levellers

For hinge lip levellers

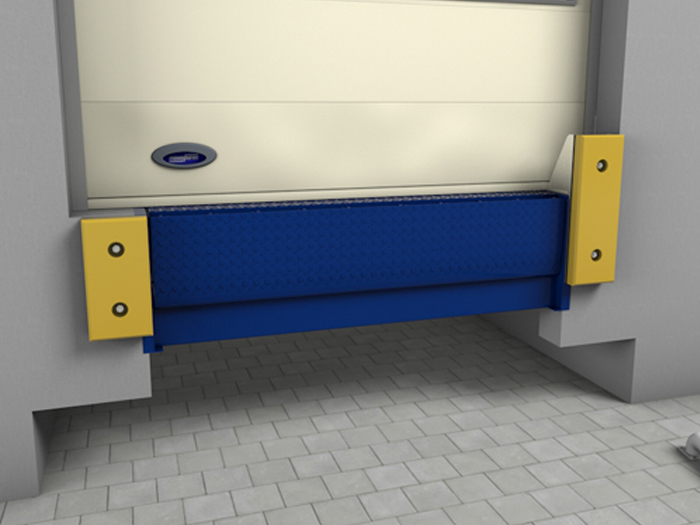

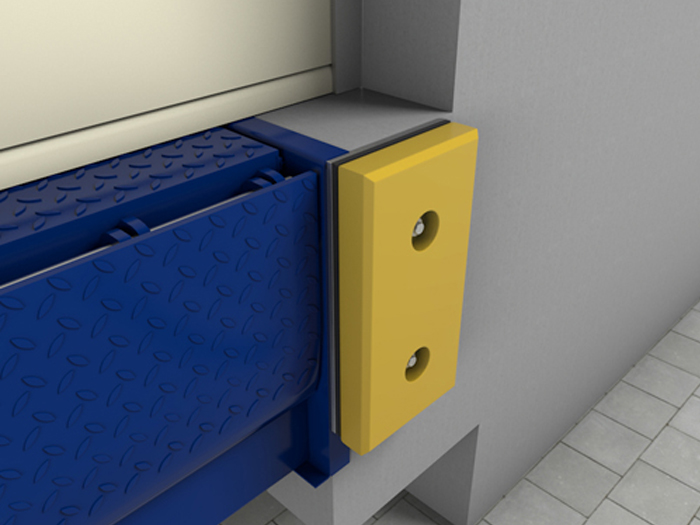

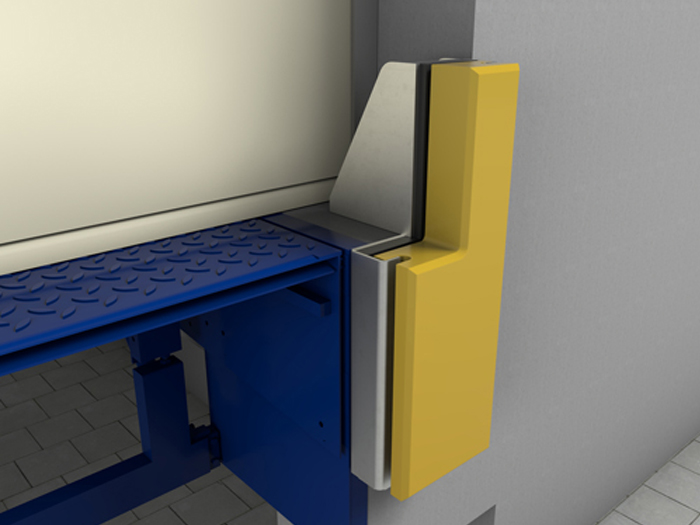

NovoSlider

NovoSlider combines the excellent properties of the Nytrex material with a long spring deflection and thus comes very close to the ideal for a dock bumper. The steel body is galvanised, which provides it with lasting protection against rust. Due to the lightweight rubber mat, the floating Nytrex material can achieve a maximum deflection of 25 mm and can follow the truck’s movements up and down.

For telescopic lip levellers

For hinge lip levellers

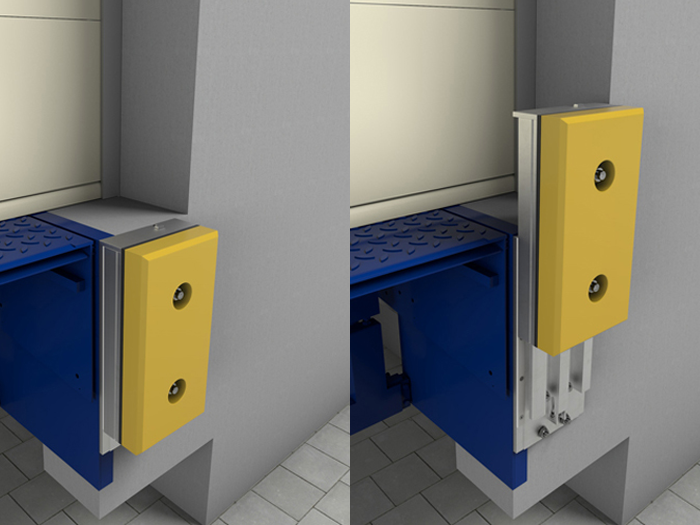

NovoSlider L swap body

NovoSlider L is mounted above the edge of the ramp and thus prevents the vehicle from driving over the bumper without limiting the loading operations.

NovoLift

NovoLift provides another way of preventing the vehicle from overrunning the dock bumper above the ramp level. A height-adjustable carriage made of steel is guided above the ramp level with the help of a pneumatic spring. After the truck has been docked, the operator can gently press the bumper down with his foot. In the lowest position, the whole carriage automatically locks into place. There is now no longer anything standing in the way of the loading operation. After loading, the carriage can easily be unlocked and runs automatically back to the top position.

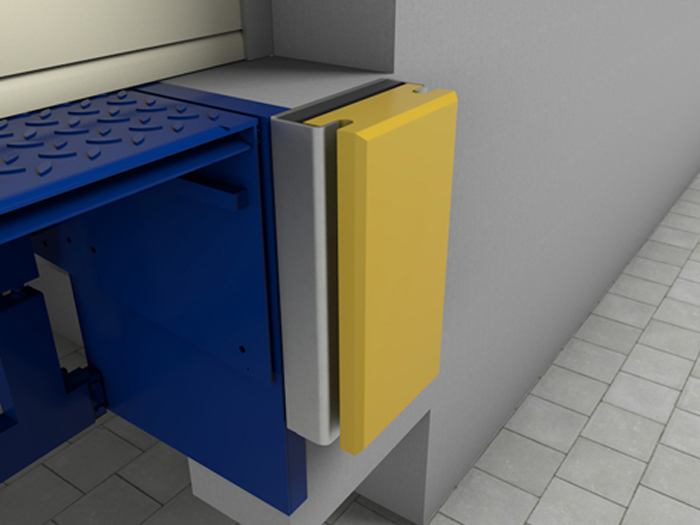

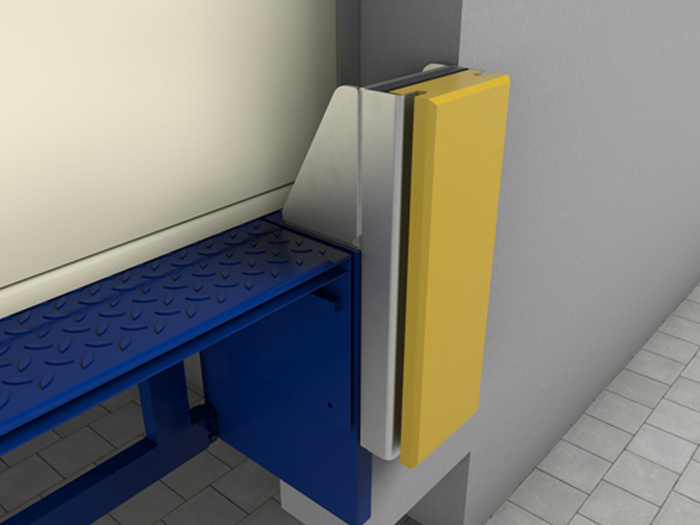

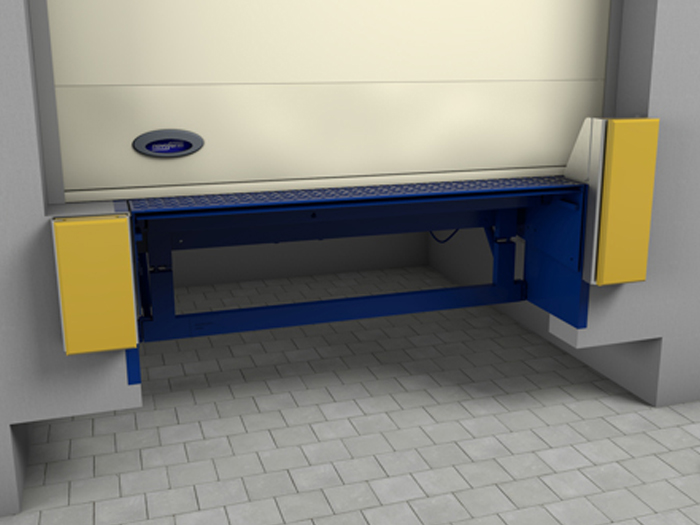

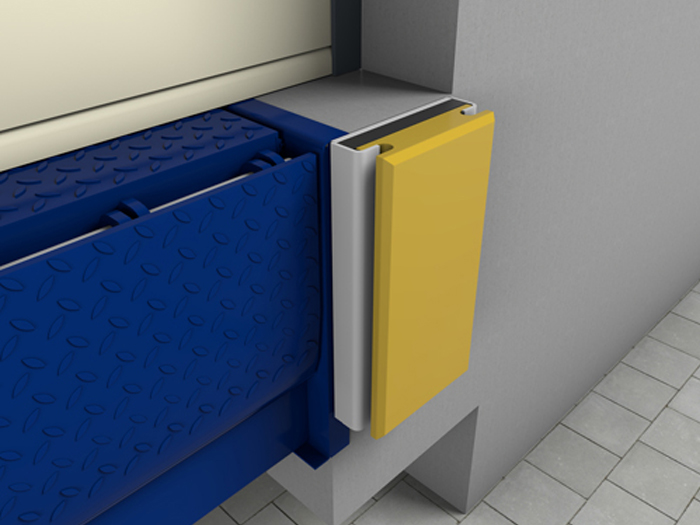

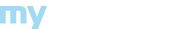

NovoEASY - Electronic approach system

As an electronic approach system with a sensor and traffic lights, NovoEASY provides perfect collision protection and ensures that the truck stops shortly before the dock bumper. This avoids damages to the building, to the truck and to the dock bumper. The sensor, which is protected within a dock bumper made of high-performance plastic, measures the distance from the truck to the loading ramp and informs the driver of this via an indicator element (e.g. traffic lights).

Product benefits:

- High-performance plastic in signal yellow

- Distance measurement (truck-building) with indication via external traffic lights

You can find further information in the data sheet!

Rubber bumpers

The rubber bumpers consist of a high-quality new rubber mixture. They are particularly abrasion-resistant and have a spring deflection of up to 20 mm.

For telescopic lip levellers

For hinge lip levellers

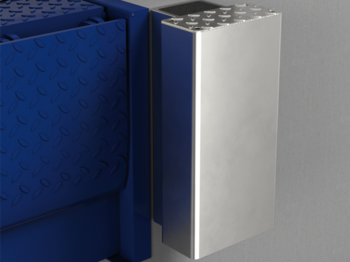

Steel bumpers

The steel bumpers consist of galvanised steel with an internal rubber core. They have a spring deflection of up to 80 mm and are wear-free.

For telescopic lip levellers

| Description | Dimensions | Article number |

|---|---|---|

| Steel bumper AZJ 500 | 500 x 250 x 200 | DS0390400 |

| Steel bumper AZJ 800 without back support | 800 x 250 x 200 | DS0390420 |

| Steel bumper AZJ 800 with back support | 800 x 250 x 200 | DS0390495 |

For hinge lip levellers

| Description | Dimensions | Article number |

|---|---|---|

| Steel bumper AZPK 500 | 500 x 250 x 140 | DS0390450 |

| Steel bumper AZPK 800 without back support | 800 x 250 x 140 | DS0390460 |

| Steel bumper AZPK 800 with back support | 800 x 250 x 140 | DS0390490 |

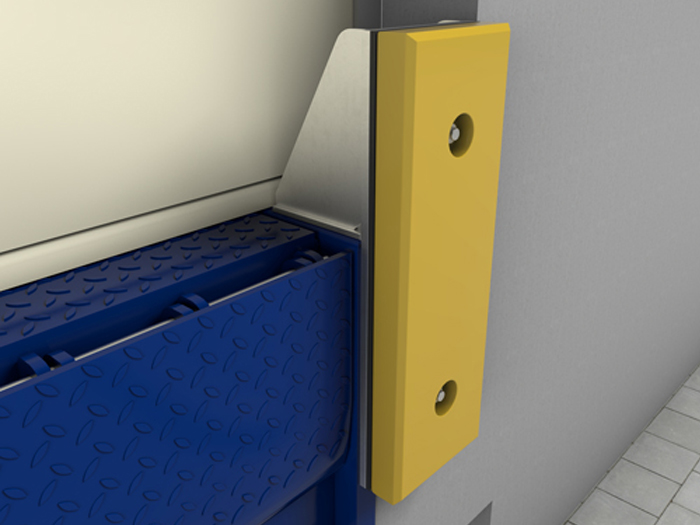

Product assessment

Different loading situations require different dock bumpers. The right solution for the customer is crucial. Therefore, mydocking offers a wide range of different systems.<br/> Five different criteria provide help with the decision-making:

| Criterion | Description |

| Building protection | Indicates how much the solution protects the building from collision damages. |

| Durability | Information on the relative durability when the bumper is used properly. |

| Spring deflection | The longer the dock bumper’s spring deflection is, the more damages to the truck and the building are prevented. |

| Life cycle cost | In addition to the costs of materials for the dock bumper, the costs for the replacement of worn-out dock bumpers and their durability are also included in the assessment of the costs. |

| Visibility | The latest assessment criterion is the visibility of the dock bumper for the truck driver. As previous products, both rubber and steel bumpers, were almost always black, there was no distinguishing feature. This changed with the development of the Nytrex® bumper. The yellow colour provides significant advantages over the other systems. That is why this criterion has found its way into the assessment. |

The more stars a model receives in one of the criteria, the higher the quality of the product.